Looking for a high-performance ABA Blown Film Extrusion Machine in Namibia?

Our Manufacturing unit is based in Kheda, Gujarat, India.

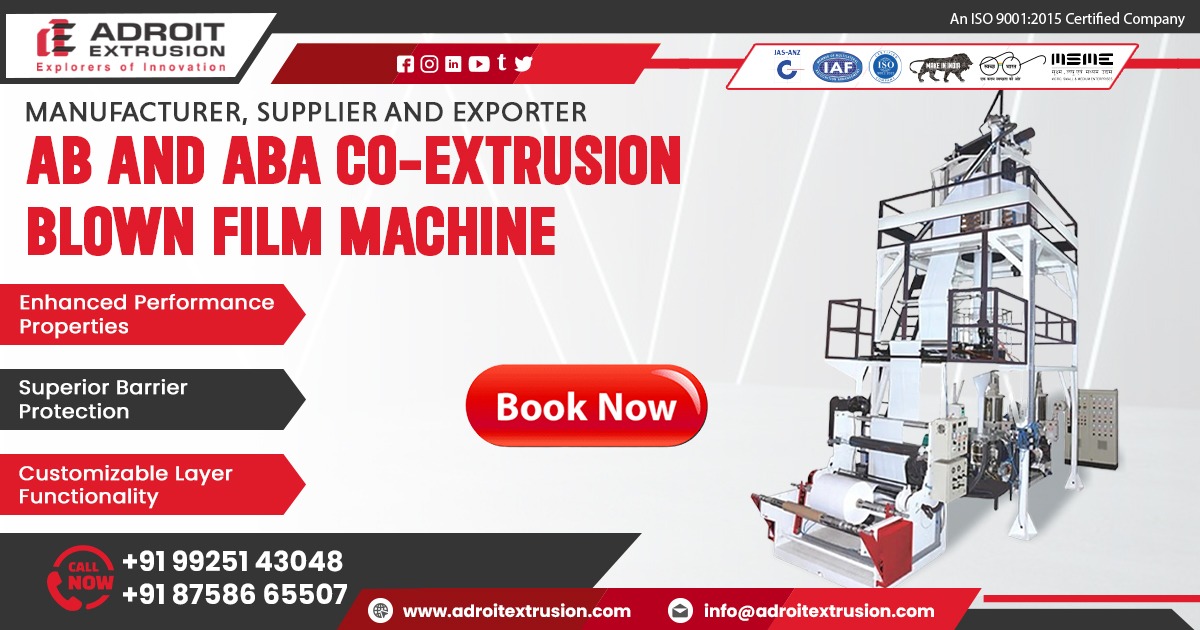

Adroit Extrusion offers advanced, energy-efficient, and highly reliable ABA film machines tailored for the growing plastic packaging industry.

Whether you’re a small-scale manufacturer or a large industrial player, our extrusion machines are engineered to meet the highest global standards—delivering unmatched quality, productivity, and cost-effectiveness.

Work of ABA Blown Film Extrusion Machine

An ABA Blown Film Extrusion Machine is designed to manufacture multi-layer plastic films used in various packaging applications.

It operates by melting polymer granules and blowing them into a tubular film that is later converted into plastic bags, wraps, and liners.

The term “ABA” refers to the three-layer co-extrusion process:

- A-layer (outer): Made from high-quality virgin or treated material for strength and finish.

- B-layer (core): Often made from recycled material to reduce cost and waste.

- A-layer (inner): Similar to the outer layer, it enhances sealing and aesthetics.

This configuration allows cost-effective production while maintaining high product quality and strength.

How Does the ABA Blown Film Extrusion Machine Work?

The process follows these key steps:

- Feeding: Raw plastic material (usually polyethylene) is fed into the extruders through hoppers.

- Melting: Electric heaters and screw mechanisms in each extruder melt the materials.

- Co-extrusion: A specialized die head combines the molten materials from three extruders (two for A-layers, one for B-layer).

- Blowing: The die head blows air to inflate the plastic into a thin tubular film bubble.

- Cooling: Air rings cool the bubble, which is then collapsed between rollers.

- Winding: The machine winds the flat film into rolls for cutting, printing, or bag-making.

This precise and consistent method ensures a uniform, high-quality film with strong mechanical properties.

Features of ABA Blown Film Extrusion Machine by Adroit Extrusion

- Three-layer co-extrusion technology

- High output with low energy consumption

- Uses recycled material for the middle layer – cost-effective & eco-friendly

- Advanced PLC control system with touchscreen interface

- Stable bubble formation with automatic air ring

- Precision die head for uniform thickness

- Optional online printing and recycling systems

- Built-in gravimetric dosing for accurate material blending

- Modular design for easy maintenance and upgrades

Uses of ABA Blown Film Extrusion Machine

The ABA film extrusion machine produces films for a wide range of industrial and commercial applications:

- Agricultural films – mulch films, greenhouse films

- Packaging films – grocery bags, shopping bags, courier bags

- Food packaging – bread bags, produce bags

- Construction films – protective sheets, liners

- Recycled film production – core layer from recycled polymers

- Retail and garbage bags – durable, puncture-resistant plastic

FAQs:

Q1. Why choose ABA over single-layer or ABC machines?

A: ABA machines are cost-effective, use less virgin material, and offer high strength and performance similar to ABC configurations—ideal for the African market.

Q2. Can this machine use recycled plastic?

A: The B-layer specifically uses recycled or lower-grade material, reducing costs without compromising quality.

Q3. Is technical support available in Namibia?

A: Adroit Extrusion offers complete installation, training, and after-sales support throughout Namibia and Southern Africa.

Q4. What materials are compatible with the machine?

A: Commonly used materials include LDPE, LLDPE, and HDPE.

Q5. What is the output capacity?

A: Depending on the model, the output ranges from 40 kg/hr to 300+ kg/hr, customizable as per your production needs.

Adroit Extrusion is an Exporter of ABA Blown Film Extrusion Machine in Namibia

including locations in Windhoek, Walvis Bay, Swakopmund, Henties Bay, Omaruru, Otjiwarongo, Okahandja, Grootfontein, Mariental, Outjo, Gobabis, Tsumeb, and Keetmanshoop.

For detailed information and inquiries, please feel free to contact us.

View Product: Click here