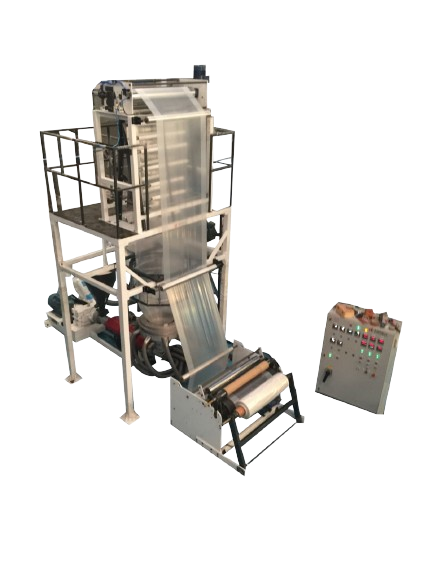

With the most customizable monolayer blown film lines available, Adroit Extrusion can accommodate a wide range of resins, applications, and output levels. Thus, customers that choose monolayer may be certain to get the highest film quality possible while using fewer resources, starting up quickly, changing over quickly, producing less waste, and being highly productive.

For processing polymers like LD, LLD, HM, and HDPE, monolayer blown film lines are provided with outputs ranging from 30 kg/hr to 200 kg/hr and lay-flat widths ranging from 500 mm to 3000 mm.

Additionally, it contains sophisticated features including a motorised bubble cage surface winder with taper tension control, a manual screen changer, an oscillating haul-off, a motorised bubble cooling system, a barrier screw, a gravimetric blending/dosing system, a liquid PIB dosing system, and a grooved feed section.

Biodegradable plastics are those that, under certain circumstances, break down into water, carbon dioxide (or methane), and biomass by microbes. New materials have been created, global standards have been put into place, and consumers are given confidence in the biodegradability of plastics to help them make decisions.

The capacity of a material to decompose and revert to its natural state is referred to as biodegradable.

Because they are both meant to safely return to the environment, compostable and biodegradable materials are comparable. Nevertheless, biodegradable materials go one step further by supplying nutrients to the soil once they have fully decomposed.

Polylactic acid (PLA) is often produced from the sugars found in sugarcane, cassava, or maize starch. It is edible, carbon neutral, and biodegradable.

The machinery is built to handle these specialized materials with ease.

The blown film line has a cutting-edge cylindrical spiral die. Short polymer flow passageways speed up material changeover and reduce polymer degradation, all of which are very beneficial for processing heat-sensitive materials.

A well-proven screw and barrel design evenly distributes the polymers, producing a flawless film.

We built the apparatus to ensure seamless processing of special polymers.

Hopper Loader, Corona Treater, Extra Die, Chiller, Heat Exchanger, Embossing Roll, Air Shaft, Two Station Surface Winder, Bi-Metalic Screw & Barrel Set, Die Rotation etc.

Adroit Extrusion leverages extensive engineering experience to produce a broad range of co-ex blown film lines. Our offerings encompass mono-layer, ABA, two-layer, three-layer, five-layer, and seven-layer technical grade films, with customizable output and widths to meet your specific needs.

WhatsApp us

We won’t spam you with irrelevant mails, we will keep you updated about our company & innovation we make.