Adroit Extrusion provides for Improve Your Film Production with ABA Blown Film Extrusion Technology in India.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

We deliver world-class equipment that enhances productivity, efficiency, and film quality.

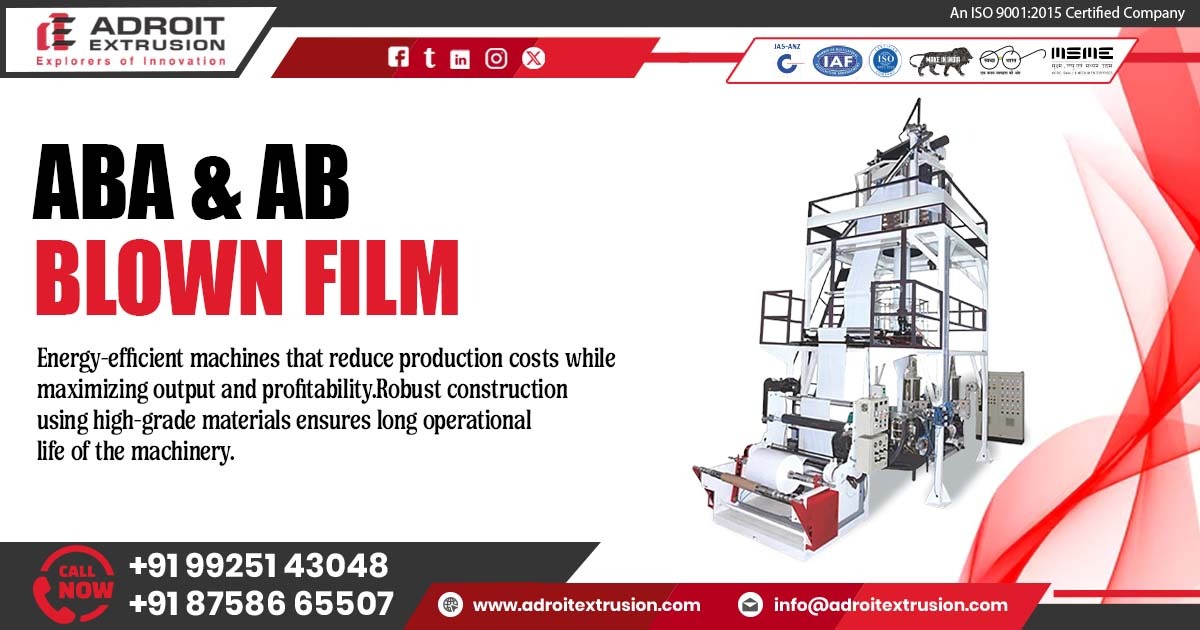

One of our flagship offerings is the ABA Blown Film Extrusion Line, designed to revolutionize film production for a variety of industries.

Our ABA Blown Film Lines use a three-layer A-B-A setup to optimize materials, boost strength, and reduce costs.

Technical Specification:

Model Name: Duoflex ABA Three Layer & AB Two Layer CO-Extrusion Blown Film Plant

Material Used: LDPE, LLDPE, HDPE, CACO3, Virgin Raw Material

Output range: 60 – 200 kg/hr

Screw Diameter: 35/45/55/65/75 (Customized)

Screw L/D ratio: 30:1 (Customized)

Layflat Film Width: 500 – 3000 mm

Thickness Range: 20 micron to 150 micron

Why Choose Our ABA Blown Film Extrusion Technology?

Cost-effective multilayer film production

Increased strength with reduced raw material consumption

Enhanced barrier properties for packaging applications

Designed for high efficiency and long operational life

Trusted by converters and manufacturers worldwide

Features of ABA Blown Film Extrusion Machines:

Dual extruder configuration

Energy-efficient motors and drives

Automatic thickness control system

High-speed air ring for better film cooling

Touchscreen HMI and PLC-based control

Precision die-head with spiral flow technology

Integrated winder for smooth roll output

Common Uses:

Carry bags

Garbage bags

Liners and sheets

Agriculture mulch films

Industrial packaging films

Laminating base films

Applications:

Packaging Industry: Food, pharmaceuticals, FMCG

Retail and Commercial Bags: Shopping and garbage bags

Agriculture: Mulch films and greenhouse covers

Industrial: Construction sheet and liners

FAQs:

Q1: What is the difference between ABA and traditional monolayer machines?

A: ABA’s three-layer design boosts strength and cuts costs, while monolayer uses one layer and more virgin material.

Q2: Can recycled material be used in ABA extrusion?

A: Yes, recycled material is ideal for the B (core) layer, making production more sustainable and cost-effective.

Q3: What types of films can be made using your ABA machines?

A: Our machines can produce LDPE, LLDPE, and HDPE films used in bags, liners, agriculture, and industrial packaging.

Q4: Is training provided with the machine?

A: Yes, we offer full on-site training and after-sales support to ensure smooth operation.

Adroit Extrusion provides ABA Blown Film Extrusion Technology in India including locations in

Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal.

Feel free to contact us if you have any more information or questions.

View Product: Click here