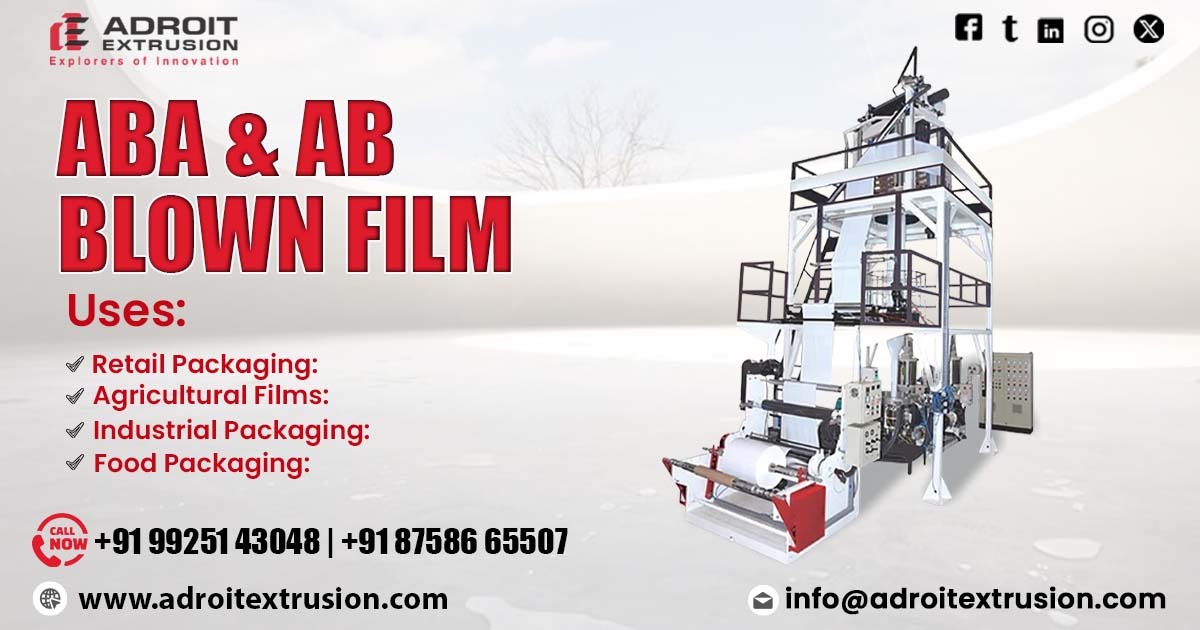

Adroit Extrusion is a leading Supplier of Premium ABA Blown Film Extrusion Machine in Punjab.

We are based in Ahmedabad, Gujarat, India.

Adroit Extrusion is a trusted name in the Indian plastic processing industry, known for its innovation, performance, and reliability.

We specialize in manufacturing ABA Blown Film Extrusion Machines that offer high efficiency, superior film quality, and cost-effective production solutions.

Advanced technology engineers our ABA film extrusion machines with precision to meet the growing demands of the packaging industry.

Whether you are looking to produce high-strength, multi-layer plastic films or reduce raw material costs, Adroit’s machines deliver unmatched performance and productivity.

What is an ABA Blown Film Extrusion Machine?

An ABA Blown Film Extrusion Machine is a type of film manufacturing equipment that uses a three-layer co-extrusion process, with two outer layers (A) and one inner layer (B). The “B” layer usually consists of a higher percentage of recycled or filler material, reducing the overall cost while maintaining film quality through virgin material in the outer layers.

Working of ABA Blown Film Extrusion Machine

- Feeding System: Three extruders feed different types of plastic granules into the system.

- Melting and Extrusion: The machine melts the plastic and passes it through a co-extrusion die.

- Bubble Formation: Air blows the extruded plastic into a bubble.

- Cooling and Sizing: An air ring cools the film bubble, and a collapsing frame sizes it.

- Haul-Off and Winding: Rollers flatten and pull the film, then wind it into rolls for further processing.

Features of ABA Blown Film Extrusion Machine

- Three-layer co-extrusion system (ABA configuration)

- Energy-efficient and high-output design

- Touchscreen control panel with PLC automation

- Precision die head for uniform film thickness

- Automatic winder system for easy roll collection

- Robust build quality for long operational life

- Capability to use recycled or filler materials in the B layer

Industries That Use ABA Blown Film Extrusion Machines

- Packaging Industry

- Agriculture (Mulch films, greenhouse films)

- Retail (Shopping and carry bags)

- Food & Beverage (Flexible packaging)

- Textile Industry (Garment bags)

- Construction (Protective sheeting)

FAQs – ABA Blown Film Extrusion Machine

Q1: What materials can be used in the ABA extrusion process?

A: Common materials include LDPE, LLDPE, HDPE, and recycled plastics.

Q2: What is the difference between ABA and ABC extrusion?

A: ABA uses two outer layers of virgin material and a middle layer of recycled or filler material, while ABC allows three different materials or layers, offering more customization.

Q3: Can I use 100% recycled material in the machine?

A: Yes, especially in the B layer. However, outer A layers should preferably use virgin material for quality.

Q4: What film thickness can be achieved?

A: Typically, film thickness ranges from 10 to 200 microns, depending on configuration.

Adroit Extrusion is a Supplier of Premium ABA Blown Film Extrusion Machine in Punjab including locations in Ludhiana, Amritsar, Jalandhar, Patiala, Bathinda, Mohali, Moga, Batala, Pathankot, Ferozpur, Abohar, Malerkotla, Khanna, Phagwara, Kapurthala, Rajpura, Muktsar, Hoshiarpur, Faridkot, Barnala, Mukerian.

Contact us today to get a tailored quote or technical consultation.

View Product: Click here