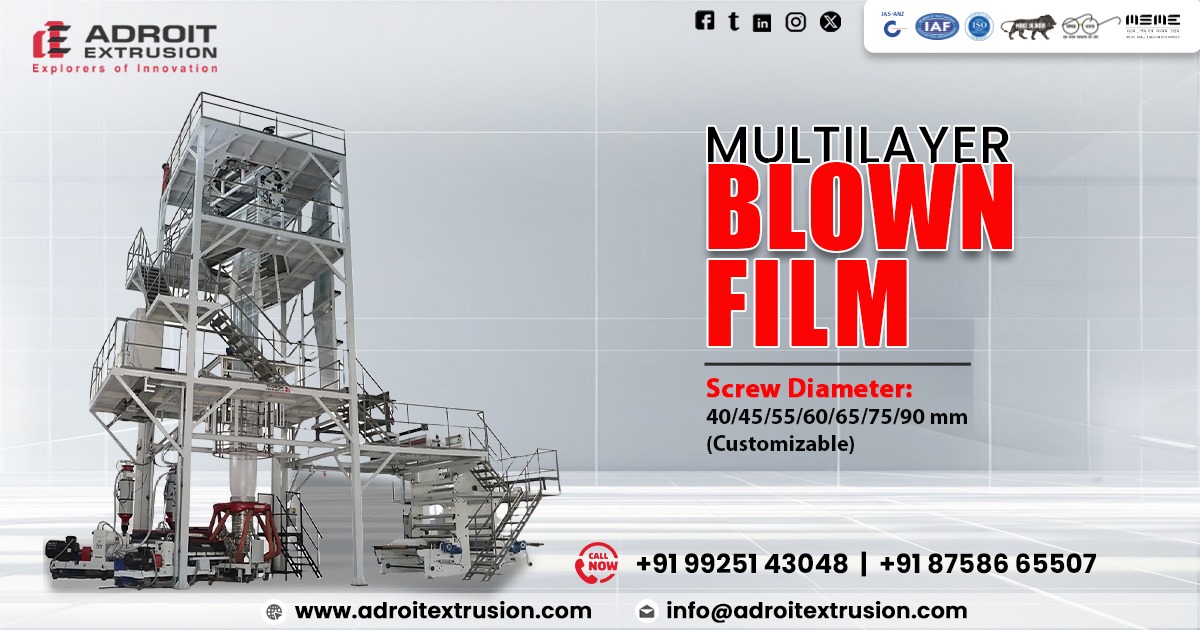

Adroit Extrusion is a reliable Multilayer Blown Film Extrusion Line Exporter

in Jordan.

Our Manufacturing unit is based in Kheda, Gujarat, India.

Multilayer blown film technology by Adroit Extrusion enables the production of high-performance films used across a wide range of packaging and industrial applications.

From basic monolayer bags to highly complex 7-layer barrier films, our cutting-edge co-extrusion lines combine multiple polymers to deliver superior film characteristics, cost-efficiency, and material versatility.

Types of Multilayer Blown Film Lines

3-Layer Blown Film Line

- Available in IBC (Internal Bubble Cooling) and Non-IBC configurations.

- Capable of producing various film types using materials such as PP, LDPE, LLDPE, HDPE, mLLDPE, Sealant Polymers, and Additives.

- Ideal for processors seeking high-quality films with balanced performance and cost-effectiveness.

- Supports layer ratio up to 1:3:1 for recipe cost reduction.

- Equipped with Modern Cylindrical Spiral Die for quick changeovers and minimized polymer degradation.

5-Layer POD (Polyolefin-Dedicated) Blown Film Line

- Optimized for all-PE structures with cost-efficient downgauging.

- Outer layers: Thin high-performance polymers.

- Inner layers: Thicker low-cost materials for significant savings.

- Meets market demands for enhanced printability, sealability, and optical properties.

- Designed to reduce final film cost while maintaining high quality.

7-Layer Barrier Film Line

- Ideal for high-barrier applications using EVOH, PA/PE, and other specialty polymers.

- Tailored for symmetrical and asymmetrical barrier film structures.

- Installed with Modern Cylindrical Spiral Die for minimal dwell time—great for heat-sensitive materials.

- Includes advanced automation features:

- Automatic thickness control (non-contact capacitive sensor)

- Gravimetric mixing and dosing system

- IBC cooling system

- Fully automatic surface winder

- Touch-screen process control interface

Features

- Multilayer Co-Extrusion: Combines multiple polymers for a single high-performance film structure.

- Advanced Automation: Touch-screen control, gravimetric dosing, and auto thickness/width control.

- Material Flexibility: Compatible with a wide range of plastic materials and masterbatches.

- Efficient Film Winding: Automated winder with tension control ensures precise winding.

- Optional Add-ons:

- Corona Treater

- Air/Water Chiller

- Hydraulic Unloading

- Digital Web Aligner

- Bi-metallic Screw & Barrel Set

- S-Wrap Cooling System

Benefits

- Reduced Raw Material Costs: Strategic layer distribution minimizes use of expensive polymers.

- Faster Changeovers: Short polymer flow pathways reduce dwell time and degradation.

- Superior Film Properties: High dart impact, puncture resistance, gloss, hot tack strength, and barrier performance.

- User-Friendly Operation: Integrated supervisory control with intuitive touch-screen interface.

- Higher ROI: Cost-effective production with enhanced flexibility and market adaptability.

How It Works

- Blown Film Co-Extrusion Process:

- Multiple polymer streams are melted and co-extruded through a die.

- The molten film is inflated into a bubble using air.

- The film bubble is cooled, collapsed, and wound into rolls.

- The final multilayer film offers targeted performance characteristics in each layer.

Applications / Uses

Multilayer blown films are widely used in industries requiring high-performance, flexible packaging. Applications include:

- Food & Liquid Packaging:

- Water Pouch Film

- Milk Film

- Edible Oil Film

- Tomato Ketchup Packaging

- Tea Packaging

- Liquid Packaging

- Industrial Packaging:

- Liners for aluminum foil, jute paper, and woven sacks

- Chemical and petrochemical packaging bags (FFS lines)

- Stretch Cling Film

- Consumer Goods:

- Grocery Bags, T-Shirt Bags, Shopping Bags

- Garment Bags

- Fresh Produce Packaging

- E-commerce and Courier:

- Courier Bags

- Tamper-proof Packaging

FAQs:

Q1: What is the difference between 3-layer, 5-layer, and 7-layer blown film lines?

A: The main difference lies in the number of layers and complexity:

- 3-layer: Balanced performance and cost, ideal for general-purpose films.

- 5-layer: Offers downgauging and better sealability/printability with cost-efficient inner layers.

- 7-layer: Advanced barrier properties using specialty polymers like EVOH and PA for high-end packaging.

Q2: Which industries can benefit from multilayer blown film?

A: Industries such as food & beverage, chemical, petrochemical, agriculture, e-commerce, and retail packaging can benefit significantly due to the enhanced properties and customization of multilayer films.

Q3: Can different materials be used in each layer?

A: Yes, each layer can be made from different polymers, allowing for customized performance like strength, gloss, puncture resistance, or barrier properties.

Q4: What raw materials can be used in these machines?

A: LDPE, LLDPE, HDPE, mLLDPE, PP, EVOH, PA, sealant polymers, additives, and masterbatches.

Q5: How does the machine control film thickness and quality?

A: Through features like automated thickness control (non-contact), gravimetric dosing, tension-controlled winding, and extrusion process control systems.

Adroit Extrusion is a reliable Multilayer Blown Film Extrusion Line Exporter

in Jordan including locations in Amman, Aqaba, Al-Karak, Madaba, As-Salt, Irbid, Zarqa, Jerash, Ash-Shajarah, Al-Husun, Aydoun, Tafilah, Ar-Ramtha, Mafraq, At Turrah, Ma’an, Sahab, Russeifa, Ajloun, Ein Al-Basha, Na’our, Al Jizah, Al Hashemiya, Mu’tah, Wadi Musa, Wadi Al-Seer, Beit Ras, An-Nuayyimah, As-Sarih, Der Abi Saeed, Fuheis, Al-Mazar, Anjara, Judayta, Kufranjah, Al Mazar al Shamali, Al Quwaysimah, As-Sukhnah, Kafr al Ma’a, Bushra, Huwwarah, and many more.

For more information and inquiries, feel free to contact us.

View Product: Click here