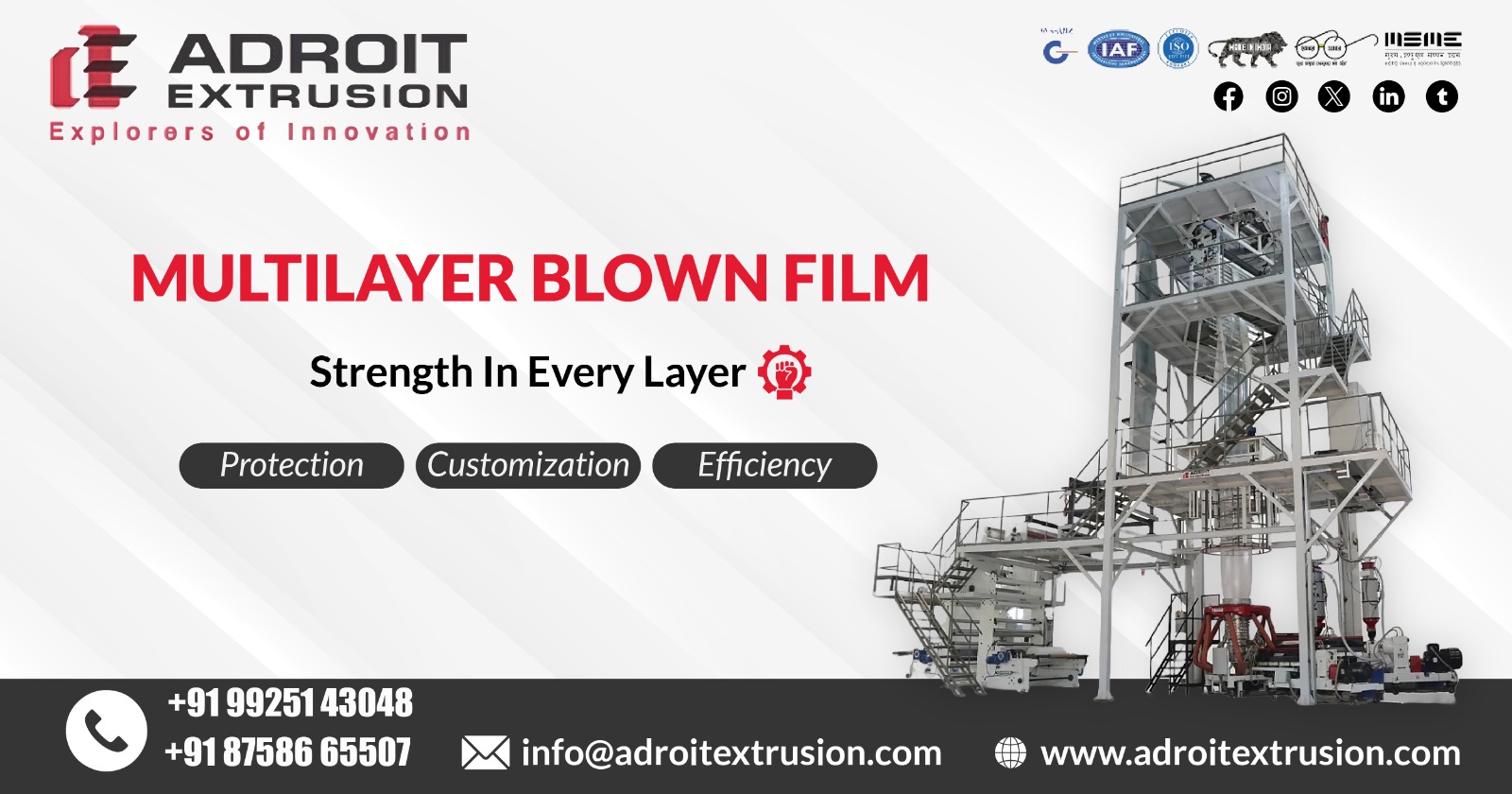

Adroit Extrusion is prominent Manufacturer and Exporter of 3 Layer Co-Extrusion Blown Film Line in Zambia.

Our Manufacturing unit is based in Kheda, Gujarat, India.

Our 3 Layer Co-Extrusion Blown Film Line is designed for the Zambian market with world-class innovation at its core.

Whether you require standard or custom configurations such as Non-IBC or IBC versions.

Our machines are built to produce high-quality multilayer films suitable for a wide variety of industrial, agricultural, and packaging applications.

Features

- Advanced Spiral Cylindrical Die Design: Ensures uniform layer distribution and optimal polymer flow.

- Layer Ratio Flexibility (Up to 1:3:1): Enables cost-effective formulations without compromising film quality.

- High Material Compatibility: Supports a broad range of materials including:

- PP, mLLDPE, LDPE, LLDPE, HDPE

- Sealant Polymers

- Additives and Masterbatches

- Optional Advanced Add-Ons:

- Gravimetric Dosing System

- Extrusion Process Control

- Air/Water Chiller

- Corona Treater

- Bi-Metallic Screw & Barrel Set

- Hydraulic Unloading System

- Digital Web Aligner

- Auto Thickness/Width Control

- Main Panel Air Conditioning

- S-Wrap Cooling System

- Empty Shaft Loading System

Technical Specification:

- Model Name: Innoflex Three Layer CO-Extrusion Blown Film Plant

- Material Used: LDPE, LLDPE, HDPE, PP, CO-POLYMER, EVA etc.

- Output Range: 100 – 500 Kg/Hr (Depends On Extruder’s Size)

- Screw Diameter: 40/45/55/60/65/75/90 MM (Customized)

- Screw L/D ratio: 30:1 (Customized)

- Layflat Width: 1000 – 3000 MM

- Thickness: 20 – 200 micron

Benefits

- Cost Efficiency: Layer ratio flexibility reduces formulation costs by minimizing use of expensive resins in non-critical layers.

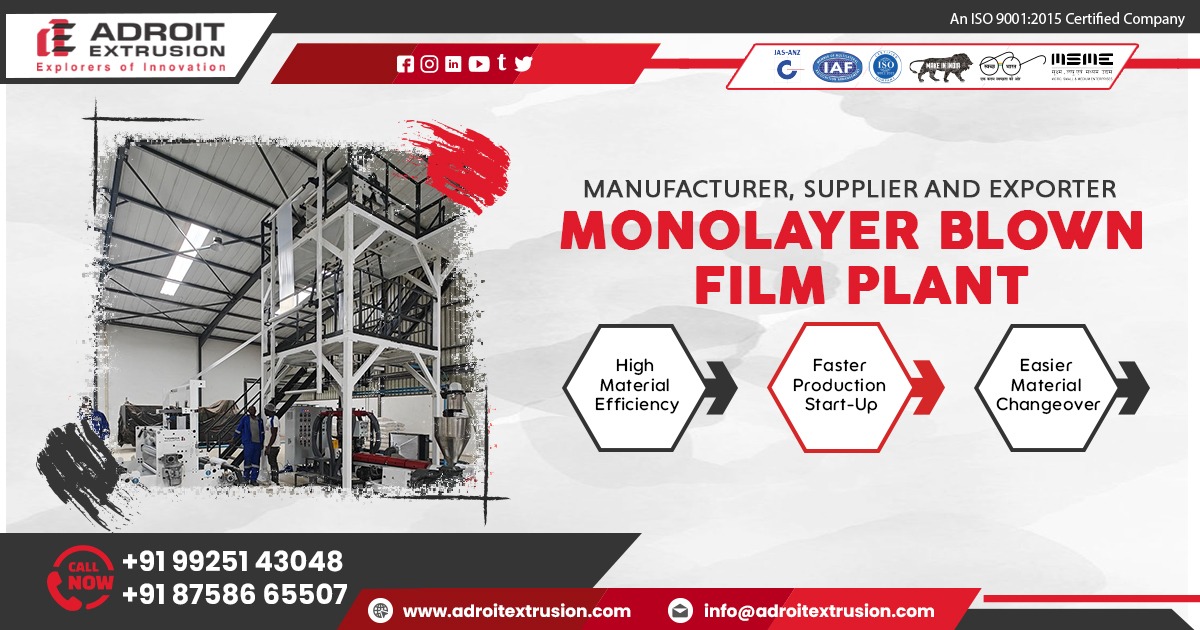

- High Productivity: Optimized design allows quick material changeovers and minimizes downtime.

- Excellent Film Quality: Produces high-strength, high-clarity films with consistent thickness and optical properties.

- Adaptability: Can be customized for specific end-use applications based on client needs.

- Durability & Longevity: Built with high-grade materials and components for long operational life.

- Heat-Sensitive Material Processing: Short polymer flow passages reduce degradation, especially valuable for sensitive resins.

Applications

This line can manufacture films used in a wide range of sectors including:

- Lamination Grade Films

- Liquid Packaging Films

- High Dart FFS Resin Sacks

- Cereal Packaging Films

- Oil Packaging Films

- Pharmaceutical & Medical Grade Films

- Pallet Hooding, Shrink & Stretch Films

- Agricultural Films: Greenhouse, Silage, Mulch Films

- Industrial Packaging: Chemical, Detergent & Soap Films

FAQs:

Q1. What materials can be processed on the 3-layer blown film line?

A: The line supports a variety of polymers including PP, LDPE, LLDPE, mLLDPE, HDPE, sealant polymers, additives, and masterbatches.

Q2. What is the advantage of the 1:3:1 layer ratio capability?

A: It allows manufacturers to optimize raw material usage by placing premium materials only where needed, reducing overall production cost.

Q3. Is the machine suitable for heat-sensitive materials?

A: Yes. The short polymer flow paths in the die head reduce degradation, making it ideal for heat-sensitive applications.

Q4. What are the benefits of using a cylindrical spiral die?

A: It ensures even layer distribution, reduces pressure drop, and enables fast material changeovers with minimal waste.

Adroit Extrusion is a is Exporter of 3 Layer Co-Extrusion Blown Film Line in Zambia

including locations in Kampala, Entebbe, Mbarara, Gulu, Jinja, Kira Town, Mukono, Lugazi, Nansana, Kasese, Mbale, Hoima, Lira, Mityana, Njeru, Masindi, Kitgum, Mubende, Pakwach, Kasubi, Mengo, Masaka, Kololo, Fort Portal, Arua, Makindye Division, Namugongo, Nakasero, Busia, Kamwokya, Bwaise, Kisoro, Ntinda and many more.

For detailed information and inquiries, please feel free to contact us.

Website: www.adroitextrusion.com

Email id: info@adroitextrusion.com

Phone No: 09925143048 | 08758665507

View Product: Click here