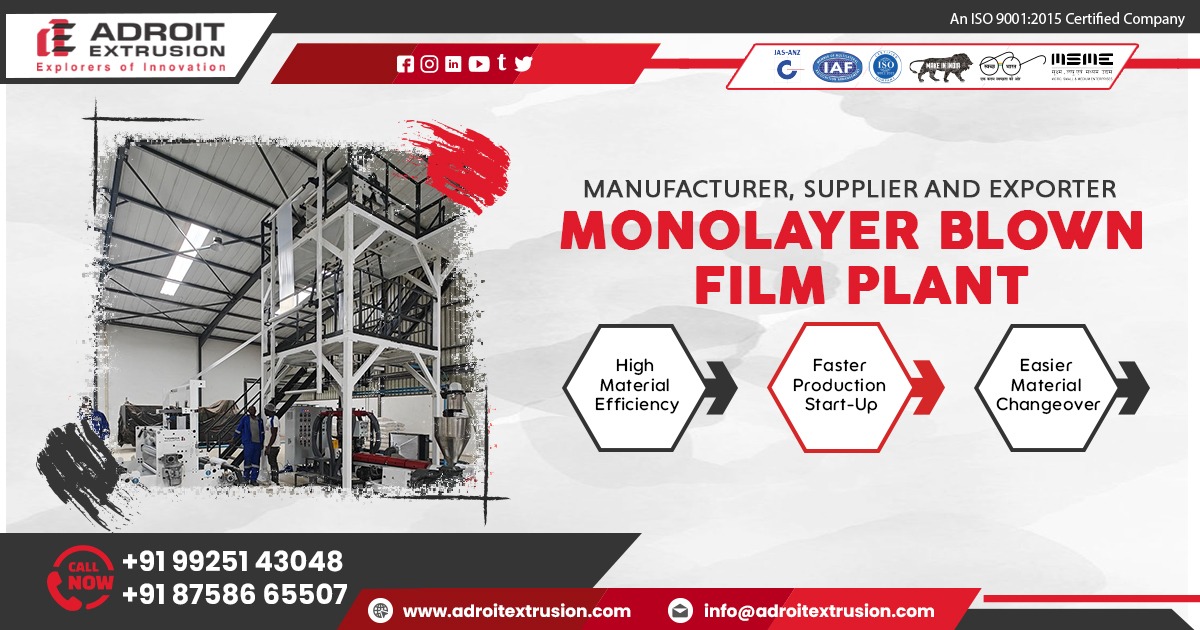

Adroit Extrusion provide Monolayer Blown Film Extrusion Plant in Chhattisgarh

Our Manufacturing unit is based in Kheda, Gujarat, India.

Adroit Extrusion manufactures premium Monolayer Blown Film Extrusion Plants in Chhattisgarh, ensuring high-performance film production solutions.

Engineered for reliability, our plants cater to packaging industries demanding efficiency, consistency, and long-term film quality performance.

Our advanced machinery meets national and international packaging standards, serving plastic film producers across Chhattisgarh and neighboring industrial hubs.

Features of Monolayer Blown Film Extrusion Plant

- High-output extruder delivers uniform film thickness with exceptional strength and clarity for multiple packaging applications.

- Energy-efficient motors reduce power consumption while maintaining consistent performance during long production shifts.

- Automatic winder system ensures precise film winding and roll formation for optimized downstream processing.

- Compact design occupies minimal space, ideal for factories with limited floor area or operational constraints.

- Heavy-duty gearbox and barrel ensure long machine life with minimal maintenance and downtime.

- Advanced cooling ring maintains film bubble stability for better gauge control and consistent film quality.

- Adjustable die head supports various film widths and thicknesses for versatile production flexibility.

- High-quality screw design ensures excellent melt homogeneity and efficient polymer processing across batches.

Technical Specification:

- Model Name: Monolayer Blown Film Plant

- Material Used: LDPE, LLDPE, HDPE, CACO3, Virgin Raw Materials etc.

- Output Range: 30 – 200 kg/hr

- Screw Diameter: 35/45/55/65/75 (Customized)

- Layflat Film Width: 500 – 3000 mm

- Thickness Range: 20 micron to 150 micron

Working Principle of Monolayer Blown Film Extrusion Plant

- Polymer granules are fed into the extruder where they are melted by heat and mechanical shearing action.

- Molten polymer passes through a die to form a continuous tubular film structure or bubble.

- Air is blown into the tube to expand it, controlling film thickness, width, and mechanical properties.

- The film bubble is cooled using an air ring to solidify the polymer into a stable film structure.

- Nip rollers collapse the bubble into flat film and guide it upward into the take-up unit.

- The take-up system maintains film tension while guiding it to the surface winding section precisely.

Uses

- Compostable Packaging Films

- Biodegradable Shopping and Carry Bags

- Agricultural Mulch Films

- Food Packaging

- Medical and Hygiene Applications

Adroit Extrusion provide Monolayer Blown Film Extrusion Plant in Chhattisgarh

including locations in Raipur, Bhilai, Bilaspur, Korba, Durg, Rajnandgaon, Raigarh, Jagdalpur, Ambikapur, Kawardha, Mahasamund, Bhatapara. Dhamtari, Baloda Bazar, Balod, Mungeli, Pandariya, Takhatpur, Bhilai Charoda, Kumhari, Bemetara, Basna, Chirmiri, Dongargarh, Khairagarh, Pithora.

For detailed information and inquiries, please feel free to contact us.

Website: www.adroitextrusion.com

Email id: info@adroitextrusion.com

Phone No: 09925143048 | 08758665507

View Product: Click here